Inventory management software can also help you save space (and ultimately money) on product and supply storage. Many companies refer to this as FIFO, meaning that the first products or supplies to come in are the first products or supplies you use or ship out.Ĭentralized inventory management also helps you when it comes time to do audits - not just that one big annual audit you may be required to do each year, but any time you want insight into your inventory levels.Īn IMS with inventory tracking also means you always know which inventory you have where, no matter how large or small your operation is. Products change over time, so you always want to make sure your oldest products in stock are the first products you ship out. Your IMS can give you instant insight not just into which products you have on hand, but also what supplies you have in stock, how much is needed in short-term and long-term, what’s been reordered, what needs to be ordered, and where everything is in the order, shipping, and receiving processes.Ĭentralized inventory management can also help you ensure you’re never stockpiling old products.

With your PAR levels set and your forecasting as fine-tuned as you can get it, an IMS can also help you centralize key functions for centralized inventory management. If your projections mean you need more product, you can quickly and instantly facilitate more orders right through your IMS platform. Within your inventory management system you can also evaluate your current marketing initiatives with insight into your leads to conversion ratios to better forecast product sales models. Not only can inventory management software help you set and maintain PAR levels, it can also help you with more accurate product forecasting.īy integrating with customer relationship management software, accounting, and sales systems, inventory management software helps you get a more accurate picture into your past sales year-over-year, a historical picture of sales over time, as well as current sales and pending orders.Ĭouple this insight with current marketing trends and the current economic climate, and you can get a good picture of what your future product needs may look like. You can even automate routine reorders so you never have to worry that you’ll be out of a product when your customers want it. Instead of risking the chance of losing a sale because a product is out of stock, you can use inventory management software to track your current inventory and send you alerts when your product levels get near your MSL or PAR levels. If your product is out of stock, you’re essentially holding the door open for your customer to walk out and into the arms of your competitors. Whichever term you prefer, an inventory management system can help you always know the minimum product amount you should have on hand. Some companies refer to this as a Minimum Stock Level (MSL) or Replenishment Balance, while others know it better as PAR levels, which is short for Periodic Automatic Replacement level.

Here are 5 ways inventory management software can save you time and money: Know Your PAR Levelsĭo you know the minimum amount of stock your company should always have on hand to meet current and future customer needs?

#Inventory control program manual

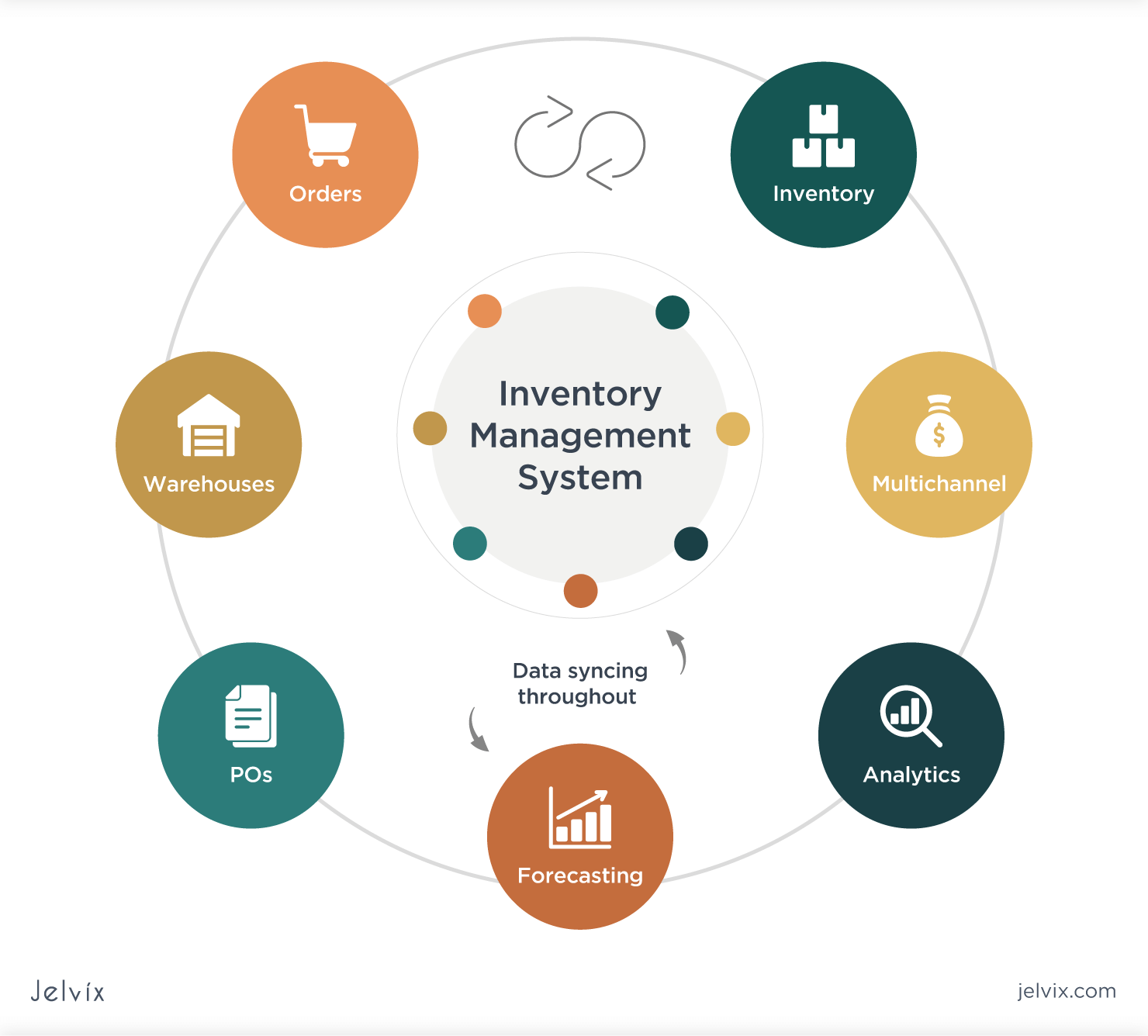

Inventory management software (IMS) can help you take control of your inventory, eliminate repetitive manual tasks, automate routine processes, and integrate with other critical functions across your business for instant insight and more information to make better business decisions. Inventory is a critical part of your business success and growth, but if not managed correctly, it can cost you time and money - especially if you’re using spreadsheets, paper manifests, or disparate software solutions across your company.ĭid you know that 43% of small and mid-size businesses (SMBs) either don’t track inventory or use a manual method? Manual tracking is prone to human error and no tracking at all means you’re likely wasting time, money, and storage space that you can better manage and improve your overall inventory efficiencies.

0 kommentar(er)

0 kommentar(er)